ABLE’s Certified Cleanroom Fabrication Facilities Ensuring Top-Tier Quality Control

Cleanroom fabrication facilities are specialized environments essential for industries like electronics, pharmaceuticals, aerospace, and medical devices, where maintaining low levels of contaminants is essential for product quality and safety. ABLE’s certifications and certified cleanroom fabrication capabilities prove our commitment to excellence, with over 1,200 square feet of carefully controlled workspace equipped with modern HEPA filters. These facilities allow us to carry out exacting procedures under strict quality control, guaranteeing that our products meet the highest global standards.

What is Cleanroom Fabrication?

A cleanroom is an enclosed space with minimal concentrations of contaminants such as dust, microorganisms in the air, aerosol particles, and chemical vapors. Controlling the environment by changing undesirable circumstances and reducing the amount of sub-micron particles present is the primary objective of a cleanroom. Cleanrooms are essential for industries including manufacturing, electronics, medical and aerospace. We categorize them based on the type of environmental control they provide.

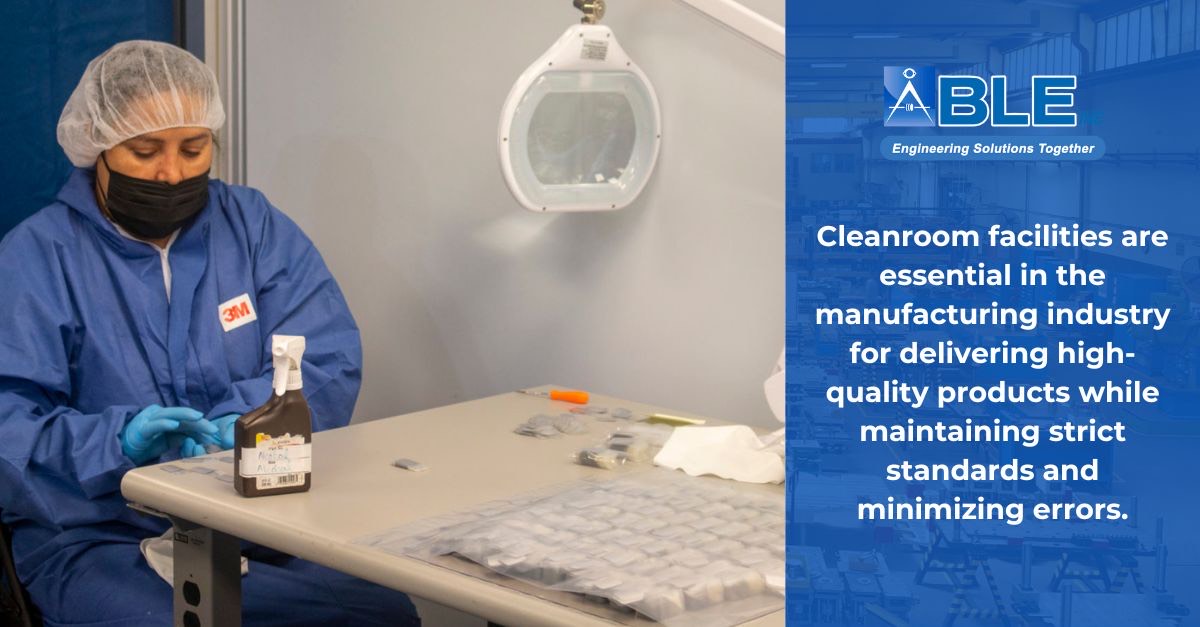

The Role of Cleanroom Facilities in Manufacturing

Cleanroom facilities are essential in the manufacturing industry for delivering high-quality products while maintaining strict standards and minimizing errors. These regulated environments are essential for industries where contamination might endanger the entire manufacturing line. Maintaining cleanrooms helps obtain certifications for both processes and products, guaranteeing that they are safe for use and satisfy standards worldwide. They defend consumers by avoiding contamination in finished goods and they protect employees by offering a secure workplace for handling hazardous materials. In order for ventilation, heating, and air conditioning systems to function well and maintain the necessary levels of cleanliness, cleanrooms are also essential to their operation. Cleanroom facilities follow strict requirements for employees, supplies, and cleaning procedures.

Importance of Cleanroom Facilities in Various Industries

Cleanrooms are essential across numerous industries, each with particular requirements:

- Electronics: In electronics manufacturing, even the slightest particles can lead to operational failures. Therefore, cleanrooms equipped with advanced air filtration systems are essential. As a result, these cleanrooms ensure defect-free production of electronic components.

- Medical: For medical device manufacturing, maintaining sterility is important to prevent mold and bacterial growth, ensuring patient safety.

- Pharmaceutical: Cleanrooms in pharmaceutical manufacturing, therefore, prevent cross-contamination and ensure the sterility of drugs, vaccines, and medical devices. Consequently, these controlled environments are essential for maintaining high standards of quality and safety in the production process.

- Aerospace: In aerospace manufacturing, cleanrooms protect sensitive components from environmental contaminants, ensuring the reliability and longevity of the final products.

- Other Industries: Cleanrooms are also essential in the high-tech, automotive, and solar energy industries, where precision and cleanliness are critical to product quality.

ABLE’s ISO-Certified Cleanroom Facilities

ABLE’s cleanroom facilities are certified to ISO-6 and ISO-7 standards, reflecting our commitment to providing a contaminant-free production environment. Our facilities feature over 1,200 square feet of workspace, ensuring strict quality control and protection throughout the manufacturing process.

ISO Certifications

- ISO-7: Known as a class 10,000 cleanroom, this certification ensures air cleanliness with no more than 10,000 particles per cubic foot. The certification ensures that our cleanroom fabrication processes, including precision cutting and assembly, are conducted in an environment with minimal airborne contaminants, thereby protecting the delicate components.

- ISO-6: Referred to as a class 1,000 cleanroom, it incorporates a HEPA filtration system to uphold air cleanliness, ensuring the presence of no more than 1,000 particles per cubic foot. The ISO-6 certification underscores our commitment to delivering the highest quality products, free from contaminants that could compromise their safety and effectiveness.

ABLE’s Advanced Cleanroom Manufacturing Capabilities

ABLE’s cleanroom facilities are built to the highest standards, creating a controlled environment for a variety of industrial operations.

Our capabilities include:

- Cleanroom Packaging: Ensures final products remain free from external contaminants.

- Cleanroom Short-Run Productions: Facilitates efficient small-batch production in a controlled environment.

- Cleanroom Assembly: Assembles components in a contamination-free space.

- Cleanroom Material Laminating: Maintains the integrity of materials through controlled lamination processes.

- Cleanroom High-Speed Rotary Die Cutting: Precision cutting in a controlled setting to ensure accuracy and quality.

- Cleanroom Flat-Bed Die Cutting: Provides another precise cutting process conducted within the cleanroom.

Top-Tier Quality Control: ABLE’s Cleanroom Fabrication Expertise

Choosing ABLE Converting means partnering with a company dedicated to precision, consistency, and excellence in cleanroom fabrication. Our cutting-edge facilities, which are accredited to ISO-6 and ISO-7 standards, provide a contaminant-free atmosphere, which is essential for manufacturing high-quality goods in industries like electronics, medicine, aircraft, and devices. Moreover, with our variety of capabilities and cutting-edge HEPA filtration systems, ABLE ensures strong quality control throughout the whole production process, making us the reliable option for important industrial tasks.

Sustaining a contamination-free manufacturing environment is essential for guaranteeing product quality and safety in today’s precision-driven industries. With cutting-edge skills including packing, assembly, and precise cutting, ABLE’s cutting-edge, ISO-6, and ISO-7 accredited cleanroom facilities show our commitment to providing high-quality products. By selecting ABLE Converting, you work with a business dedicated to accuracy, reliability, and excellence, guaranteeing that the highest standards of quality and cleanliness are met by your products.

Ready to experience high standards and quality on your products? Contact us at ABLE Converting now!

References:

https://able123converting.com/capabilities/clean-fabrication-facilities/

https://able123converting.com/blog/able-converting-leading-cleanroom-facilities/

https://able123converting.com/blog/cleanroom-facilities/

https://www.linkedin.com/pulse/understanding-cleanroom-classifications-iso-8-7-6-5-charles-lipeles/